| Machine Model | LX3015/4015/6015CT |

| Power of Generator | 1000/1500/2000W (optional) |

| Dimension | 4771*8145*2005mm(About) |

| Working Area | 1500*3000mm(Other size can be customized) |

| Repeated Positioning Accuracy | ±0.02mm |

| Max Running Speed | 120m/min |

| Max Acceleration | 1.5G |

| Specified Voltage And Frequency | 380V 50/60HZ |

LXSHOW FT series fiber laser cutting machine can not only cut metal plates,but also metal pipes. It has many uses and can save the space of more than 50%,which effectively improve productivity.

LXSHOW FT series fiber laser cutting machine can not only cut metal plates,but also metal pipes. It has many uses and can save the space of more than 50%,which effectively improve productivity. Easyto operate evenby green hands, Match with 20000 process data on its graphical programming interface, Compatible with multile graphic files, incl. DXF DWG, PLT and NC code, Improve stock layout and material utilization by 20% and 9.5% by its built-in nesting software, with no limit of quantity of spare parts, Support language: English, Spanish, Portuguese, Russian, German, French, Italian, Japanese, Korean, Dutch, Czech, Simplified Chinese, traditional Chinese.●New man-machine interaction pattern ●Flexible/batch processingmode ●Uitra-high-speed scanning & ctting with micro-connection ●Real-ime monitoring of core components ●Active reminder of machine maintenance ●Bult-in nesting software, save labor force

Easyto operate evenby green hands, Match with 20000 process data on its graphical programming interface, Compatible with multile graphic files, incl. DXF DWG, PLT and NC code, Improve stock layout and material utilization by 20% and 9.5% by its built-in nesting software, with no limit of quantity of spare parts, Support language: English, Spanish, Portuguese, Russian, German, French, Italian, Japanese, Korean, Dutch, Czech, Simplified Chinese, traditional Chinese.●New man-machine interaction pattern ●Flexible/batch processingmode ●Uitra-high-speed scanning & ctting with micro-connection ●Real-ime monitoring of core components ●Active reminder of machine maintenance ●Bult-in nesting software, save labor force The single-module continuous fiber laser has high electro-optical conversion efficiency, good beam quality, high energy density, wide modulation frequency, strong reliability, long life and maintenance-free operation.Generator service life: The service life of the generator (theoretical value) is 10,00000 hours. That means if you use it 8 hours a day, it can last about 33 years.

The single-module continuous fiber laser has high electro-optical conversion efficiency, good beam quality, high energy density, wide modulation frequency, strong reliability, long life and maintenance-free operation.Generator service life: The service life of the generator (theoretical value) is 10,00000 hours. That means if you use it 8 hours a day, it can last about 33 years.LXSHOW fiber laser cutting machine is equipped with German Atlanta rack, Japanese Yaskawa motor and Taiwan Hiwin Rails. The positioning accuracy of the machine tool can be 0.02mm and the cutting acceleration is 1.5G. The working life is up to more than 15 years.

Application Materials

Fiber Laser Metal Cutting Machine is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, etc.

Application Industries

Fiber Laser Cutting Machines are widely used in manufacture Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Model Number: LX3015/4015/6015CT Lead time: 15-25 working days(About) Payment Term: T/T;Alibaba trade assurance;West Union;Payple;L/C. Machine Size: (About)4771*8145*2005mmMachine weight: 5000KG(About) Brand: LXSHOW Warranty: 3 years Shipping: By sea/By land

Model Number: LX3015/4015/6015CT Lead time: 15-25 working days(About) Payment Term: T/T;Alibaba trade assurance;West Union;Payple;L/C. Machine Size: (About)4771*8145*2005mmMachine weight: 5000KG(About) Brand: LXSHOW Warranty: 3 years Shipping: By sea/By landDust-proof

All electrical components and laser source are built-in to the independent control cabinet with a dust-proof design to prolong the lifespan of the electrical components.

Automatic Thermostat

The control cabinet is equipped with air conditioner for automatic constant temperature.This can prevent excessive temperature damage to components in summer.

The high efficiency cooling: Collimating lens and focus lens group are cooling structure, increase cooling airflow nozzle at the same time, the effective protection of nozzle, the ceramic body, prolonged work time.Chase the light aperture: Through the pore diameter of 35 mm, effectively reduce the stray light interference, ensuring cutting quality and service life.Automatic focus: Automatic focus, reduce human intervention, focusing speed 10 m/min, repeat accuracy of 50 microns.Tips: The consumable parts of the fiber laser cutting machine include: cutting nozzle (≥500h), protective lens (≥500h), focusing lens (≥5000h), collimator lens (≥5000h), ceramic body (≥10000h), you are buying the machine You can buy some consumable parts as an option.

The high efficiency cooling: Collimating lens and focus lens group are cooling structure, increase cooling airflow nozzle at the same time, the effective protection of nozzle, the ceramic body, prolonged work time.Chase the light aperture: Through the pore diameter of 35 mm, effectively reduce the stray light interference, ensuring cutting quality and service life.Automatic focus: Automatic focus, reduce human intervention, focusing speed 10 m/min, repeat accuracy of 50 microns.Tips: The consumable parts of the fiber laser cutting machine include: cutting nozzle (≥500h), protective lens (≥500h), focusing lens (≥5000h), collimator lens (≥5000h), ceramic body (≥10000h), you are buying the machine You can buy some consumable parts as an option.

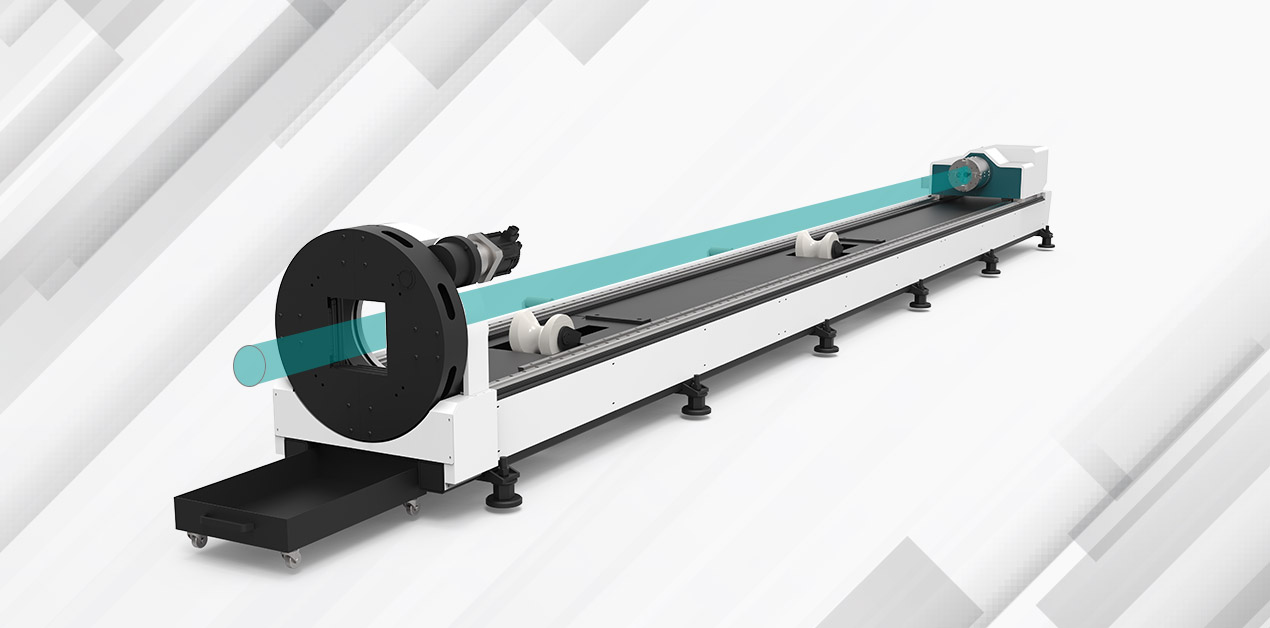

It adopts an pneumatic clamp design on both sides and it can modulate the center automatically.The diagonal adjustable range is 20-220mm(320/350 is optional)The Segmented Rectangle laser Tube Welded Bed, The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a number of rectangular tubes. Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the bed, it also increases the resistance and stability of the guide rai so as to effectively avoid the deformation of the bed.

It adopts an pneumatic clamp design on both sides and it can modulate the center automatically.The diagonal adjustable range is 20-220mm(320/350 is optional)The Segmented Rectangle laser Tube Welded Bed, The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a number of rectangular tubes. Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the bed, it also increases the resistance and stability of the guide rai so as to effectively avoid the deformation of the bed. High speed cutting: 25 mm carbon steel sheet pre punch time < 3 s @ 3000 w, greatly improve cutting efficiency.The chucks are 3 times faster than electric chucks due to one-key clamping and auto centering. With large and constant clamping force, heavy tubes will be clamping stably. Two rows of rollers are adopted for a wide range of clamping and high cutting precision.Rotary Length: 6m standard,8m and other size can be customized.

High speed cutting: 25 mm carbon steel sheet pre punch time < 3 s @ 3000 w, greatly improve cutting efficiency.The chucks are 3 times faster than electric chucks due to one-key clamping and auto centering. With large and constant clamping force, heavy tubes will be clamping stably. Two rows of rollers are adopted for a wide range of clamping and high cutting precision.Rotary Length: 6m standard,8m and other size can be customized. Rotary Diameter: 160/220mm is standard. Other size can be customized.Chuck: Both pneumatic control

Rotary Diameter: 160/220mm is standard. Other size can be customized.Chuck: Both pneumatic control Automatic pneumatic chuck, adjustable and stable, clamping range is wider and clamping force is larger. Non - destructive pipe clamping, fast automatic centering and clamping pipe, performance is more stable. The chuck size is smaller, rotation inertia is low, and dynamic performance is strong. Self-centering pneumatic chuck, gear transmission mode, higher transmission efficiency, long working life and high work reliability.It employs intelligent tube support design, which can solve the deformation problems in the process of long tube cutting

Automatic pneumatic chuck, adjustable and stable, clamping range is wider and clamping force is larger. Non - destructive pipe clamping, fast automatic centering and clamping pipe, performance is more stable. The chuck size is smaller, rotation inertia is low, and dynamic performance is strong. Self-centering pneumatic chuck, gear transmission mode, higher transmission efficiency, long working life and high work reliability.It employs intelligent tube support design, which can solve the deformation problems in the process of long tube cutting Generator Brand: Raycus/JPT/MAX/IPG/Nlight

Generator Brand: Raycus/JPT/MAX/IPG/Nlight