| Machine Model | LX3015E |

| Power of Generator | 3000/4000/6000/8000/10000/12000W |

| Dimension | 2650*8150*1860mm |

| Working Area | 1500*3000mm |

| Repeated Positioning Accuracy | ±0.02mm |

| Max Running Speed | 120m/min |

| Max Acceleration | 1.5G |

| Specified Voltage And Frequency | 380V 50/60HZ |

Max. no-load speed 120m/min, max. acceleration 1.2G, 40% faster than 2nd generation, accelerate from 0m/min to 100m/min in 3.2s.

Max. no-load speed 120m/min, max. acceleration 1.2G, 40% faster than 2nd generation, accelerate from 0m/min to 100m/min in 3.2s. ●Easyto operate evenby green hands ●Match with 20000 process data on its graphical programming interface ●Compatible with multile graphic files, incl. DXF DWG, PLT and NC code ●Improve stock layout and material utilization by 20% and 9.5% by its built-in nesting software, with no limit of quantity of spare parts ●Support language: English, Spanish, Portuguese, Russian, German, French, Italian, Japanese, Korean, Dutch, Czech, Simplified Chinese, traditional Chinese.

●Easyto operate evenby green hands ●Match with 20000 process data on its graphical programming interface ●Compatible with multile graphic files, incl. DXF DWG, PLT and NC code ●Improve stock layout and material utilization by 20% and 9.5% by its built-in nesting software, with no limit of quantity of spare parts ●Support language: English, Spanish, Portuguese, Russian, German, French, Italian, Japanese, Korean, Dutch, Czech, Simplified Chinese, traditional Chinese. The generator's using life (theoretical value) is 10,00000 hours. This means that if you use it for 8 hours a day, it can be used for about 33 years.Generator Brand: JPT/Raycus/IPG/MAX/Nlight

The generator's using life (theoretical value) is 10,00000 hours. This means that if you use it for 8 hours a day, it can be used for about 33 years.Generator Brand: JPT/Raycus/IPG/MAX/NlightLXSHOW fiber laser cutting machine is equipped with German Atlanta rack, Japanese Yaskawa motor and Taiwan Hiwin Rails. The positioning accuracy of the machine tool can be 0.02mm and the cutting acceleration is 1.5G. The working life is up to more than 15 years.

Application Materials

Fiber Laser Metal Cutting Machine is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, etc.

Application Industries

Fiber Laser Cutting Machines are widely used in manufacture Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Model Number: LX3015E Lead time: 15-30 working days Payment Term: T/T;Alibaba trade assurance;West Union;Payple;L/C. Machine Size: (About) Exchange table Machine size: 5200*3000*2400mmWater chiller +Controller: 1830*920*2110mm Machine weight: 7000KG Brand: LXSHOW Warranty: 3 years Shipping: By sea/By land

Model Number: LX3015E Lead time: 15-30 working days Payment Term: T/T;Alibaba trade assurance;West Union;Payple;L/C. Machine Size: (About) Exchange table Machine size: 5200*3000*2400mmWater chiller +Controller: 1830*920*2110mm Machine weight: 7000KG Brand: LXSHOW Warranty: 3 years Shipping: By sea/By landDust-proof

All electrical components and laser source are built-in to the independent control cabinet with a dust-proof design to prolong the lifespan of the electrical components.

Automatic Thermostat

The control cabinet is equipped with air conditioner for automatic constant temperature.This can prevent excessive temperature damage to components in summer.

The high efficiency cooling: Collimating lens and focus lens group are cooling structure, increase cooling airflow nozzle at the same time, the effective protection of nozzle, the ceramic body, prolonged work time.Automatic focus: Automatic focus, reduce human intervention, focusing speed 10 m/min, repeat accuracy of 50 microns.High speed cutting: 25 mm carbon steel sheet pre punch time < 3 s @ 3000 w, greatly improve cutting efficiency.

The high efficiency cooling: Collimating lens and focus lens group are cooling structure, increase cooling airflow nozzle at the same time, the effective protection of nozzle, the ceramic body, prolonged work time.Automatic focus: Automatic focus, reduce human intervention, focusing speed 10 m/min, repeat accuracy of 50 microns.High speed cutting: 25 mm carbon steel sheet pre punch time < 3 s @ 3000 w, greatly improve cutting efficiency.

It is welded by heavy steel plate, the current mainstream bed structure, high stability; Effect force annealing treatment, high mechanical strength, not easy to deform; Reinforcing ribs are arranged inside the bed to increase the strength and tensile resistance of the bed, and effectively avoid deformation of the bed; The weight of the bed, the small vibration of the machine, and the good shock resistance ensure the improvement of cutting accuracy. It adopts an up and down exchange platform; The converter is responsible for controlling the exchanging motor; The machine is able to finish the platform exchanging within 15s.Integral cast aluminum beam, light weight, high strength, no deformation.

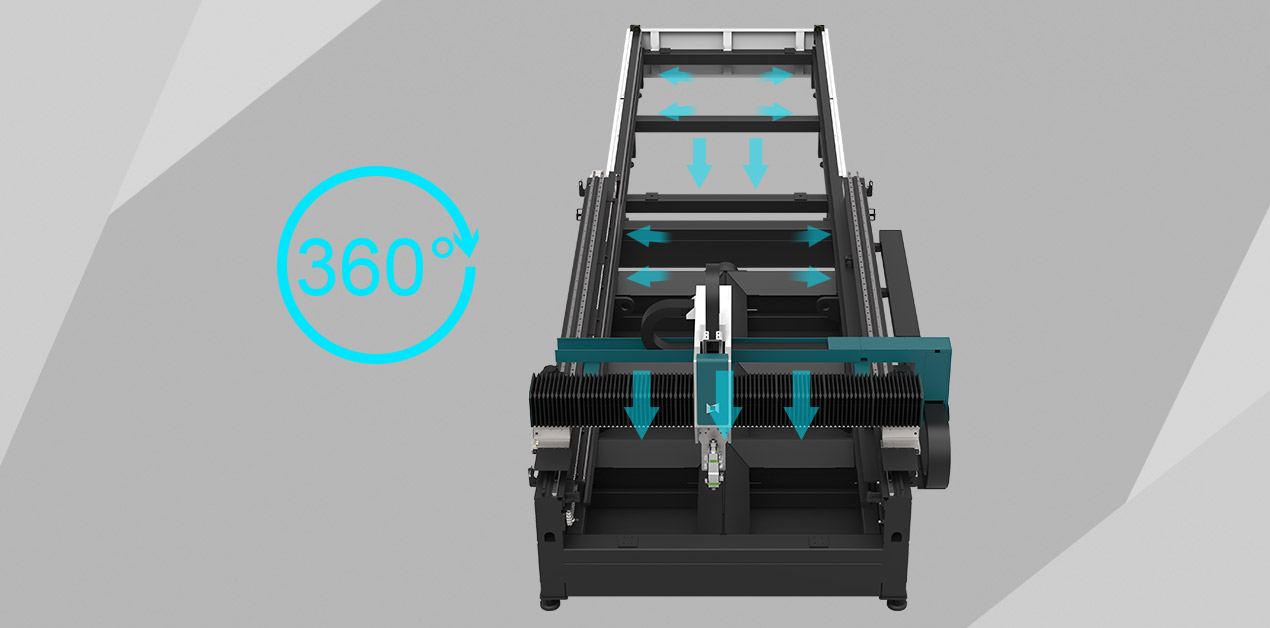

It is welded by heavy steel plate, the current mainstream bed structure, high stability; Effect force annealing treatment, high mechanical strength, not easy to deform; Reinforcing ribs are arranged inside the bed to increase the strength and tensile resistance of the bed, and effectively avoid deformation of the bed; The weight of the bed, the small vibration of the machine, and the good shock resistance ensure the improvement of cutting accuracy. It adopts an up and down exchange platform; The converter is responsible for controlling the exchanging motor; The machine is able to finish the platform exchanging within 15s.Integral cast aluminum beam, light weight, high strength, no deformation. Tips: The consumable parts of the fiber laser cutting machine include: cutting nozzle (≥500h), protective lens (≥500h), focusing lens (≥5000h), collimator lens (≥5000h), ceramic body (≥10000h), you are buying the machine You can buy some consumable parts as an option.Adopt the latest cutting-edge tobacco control technology, Each section of the bed has a smoke exhaust device.Powerful negative pressure 360° adsorption, Axial fan wind direction surrounds blowing smoke downward, Full 360° strong adsorption and consistent smoke exhaust, Effectively purify the smoke and dust on the top of the enclosed cutting platform, Improve purification efficiency and reject lens contamination.

Tips: The consumable parts of the fiber laser cutting machine include: cutting nozzle (≥500h), protective lens (≥500h), focusing lens (≥5000h), collimator lens (≥5000h), ceramic body (≥10000h), you are buying the machine You can buy some consumable parts as an option.Adopt the latest cutting-edge tobacco control technology, Each section of the bed has a smoke exhaust device.Powerful negative pressure 360° adsorption, Axial fan wind direction surrounds blowing smoke downward, Full 360° strong adsorption and consistent smoke exhaust, Effectively purify the smoke and dust on the top of the enclosed cutting platform, Improve purification efficiency and reject lens contamination.  The lightweight gantry ensures that the metal laser cutting machine has a high moving speed, good dynamic performance, and improved processing efficiency.Honeycomb Compression Structure Design Compliant with Spacecraft Design StandardsExchange Table: It adopts an up and down exchange platform; The converter is responsible for controlling the exchanging motor; The machine is able to finish the platform exchanging within 15s.

The lightweight gantry ensures that the metal laser cutting machine has a high moving speed, good dynamic performance, and improved processing efficiency.Honeycomb Compression Structure Design Compliant with Spacecraft Design StandardsExchange Table: It adopts an up and down exchange platform; The converter is responsible for controlling the exchanging motor; The machine is able to finish the platform exchanging within 15s.