| Machine Model | LX12025F | LX12020F | LX16030F | LX20030F | LX24030F |

| Working Area | 12100*2550 | 12100*2050 | 16500*3200 | 20500*3200 | 24500*3200 |

| power of Generator | 4kw-20kw | ||||

| X/Y-axis Positioning Accuracy | 0.02mm/m | ||||

| X/Y-axis Repositioning Accuracy | 0.01mm/m | ||||

| X/Y-axis Max. linkage speed | 80m/min | ||||

The separate design of the bed and worktable ensures the high dynamic performance of the machine tool and the service life of the machine tool. It can adapt to workpieces up to 3200mm wide and 50mm thick.LXSHOW provides the flexibility to deal with ultra-large-format thick plates, segmented splicing bed, and the format can be customized on demand.

The separate design of the bed and worktable ensures the high dynamic performance of the machine tool and the service life of the machine tool. It can adapt to workpieces up to 3200mm wide and 50mm thick.LXSHOW provides the flexibility to deal with ultra-large-format thick plates, segmented splicing bed, and the format can be customized on demand. For reducing damage to the work bed during laser working, LXSHOW Innovated the new work bed by adding four slings, and the life span of the fiber laser cutting machine work bed will be doubled.

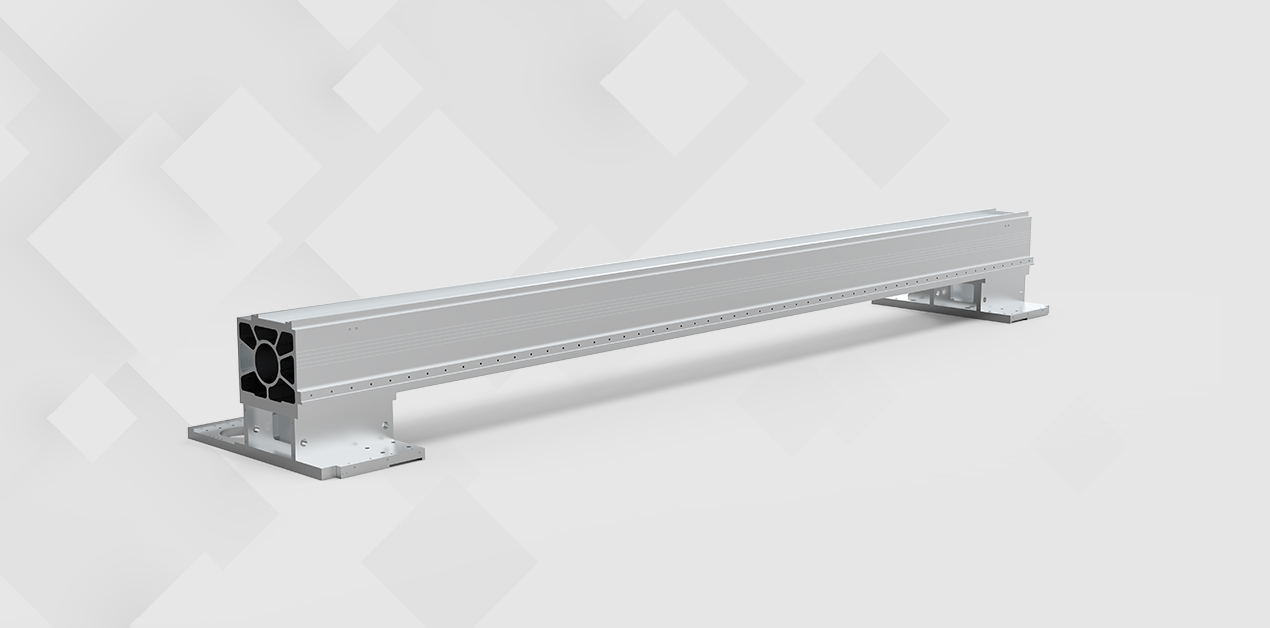

For reducing damage to the work bed during laser working, LXSHOW Innovated the new work bed by adding four slings, and the life span of the fiber laser cutting machine work bed will be doubled. It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed. Easyto operate evenby green hands, Match with 20000 process data on its graphical programming interface, Compatible with multile graphic files, incl. DXF DWG, PLT and NC code, Improve stock layout and material utilization by 20% and 9.5% by its built-in nesting software, with no limit of quantity of spare parts, Support language: English, Spanish, Portuguese, Russian, German, French, Italian, Japanese, Korean, Dutch, Czech, Simplified Chinese, traditional Chinese.●New man-machine interaction pattern ●Flexible/batch processingmode ●Uitra-high-speed scanning & ctting with micro-connection ●Real-ime monitoring of core components ●Active reminder of machine maintenance ●Bult-in nesting software, save labor force

Easyto operate evenby green hands, Match with 20000 process data on its graphical programming interface, Compatible with multile graphic files, incl. DXF DWG, PLT and NC code, Improve stock layout and material utilization by 20% and 9.5% by its built-in nesting software, with no limit of quantity of spare parts, Support language: English, Spanish, Portuguese, Russian, German, French, Italian, Japanese, Korean, Dutch, Czech, Simplified Chinese, traditional Chinese.●New man-machine interaction pattern ●Flexible/batch processingmode ●Uitra-high-speed scanning & ctting with micro-connection ●Real-ime monitoring of core components ●Active reminder of machine maintenance ●Bult-in nesting software, save labor force Application Materials

Fiber Laser Metal Cutting Machine is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, etc.

Application Industries

Fiber Laser Cutting Machines are widely used in manufacture Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

FOB Reference Price Range USD:100000-125000 Model Number:LX12025F Lead time:10-25 working days Payment Term:T/T;Alibaba trade assurance;West Union;Payple;L/C Machine Size:15000*4700*1830Machine Weight:19924.97kg Brand:LXSHOW Warranty:3 years Shipping:By sea/By land

FOB Reference Price Range USD:100000-125000 Model Number:LX12025F Lead time:10-25 working days Payment Term:T/T;Alibaba trade assurance;West Union;Payple;L/C Machine Size:15000*4700*1830Machine Weight:19924.97kg Brand:LXSHOW Warranty:3 years Shipping:By sea/By land Adopt the latest cutting-edge tobacco control technology Each section of the bed has a smoke exhaust device Powerful negative pressure 360° adsorption Axial fan wind direction surrounds blowing smoke downward Full 360° strong adsorption and consistent smoke exhaust Effectively purify the smoke and dust on the top of the enclosed cutting platform Improve purification efficiency and reject lens contamination Net follow-up, wisdom grows by quality The smoke exhaust device automatically senses the laser cutting position Turn on precise smoke exhaust, follow-up smart smokingCreate a concealed cavity, fully enclosed smoke control and clean smoke.• motorized focus position adjustment for automatic machine setup and piercing work • lightweight and slim design created for fast acceleration and cutting speed • drift-free, fast-reacting distance measurement • permanent protective window monitoring • automated piercing with PierceTec • water cooling of the sheet metal with CoolTec • completely dustproof beam path with protective windows • LED operating status display • output of all sensor data via WLAN to APP and machine control possible • pressure monitoring in the nozzle area (gas cutting) and in the head

Adopt the latest cutting-edge tobacco control technology Each section of the bed has a smoke exhaust device Powerful negative pressure 360° adsorption Axial fan wind direction surrounds blowing smoke downward Full 360° strong adsorption and consistent smoke exhaust Effectively purify the smoke and dust on the top of the enclosed cutting platform Improve purification efficiency and reject lens contamination Net follow-up, wisdom grows by quality The smoke exhaust device automatically senses the laser cutting position Turn on precise smoke exhaust, follow-up smart smokingCreate a concealed cavity, fully enclosed smoke control and clean smoke.• motorized focus position adjustment for automatic machine setup and piercing work • lightweight and slim design created for fast acceleration and cutting speed • drift-free, fast-reacting distance measurement • permanent protective window monitoring • automated piercing with PierceTec • water cooling of the sheet metal with CoolTec • completely dustproof beam path with protective windows • LED operating status display • output of all sensor data via WLAN to APP and machine control possible • pressure monitoring in the nozzle area (gas cutting) and in the head

LXSHOW fiber laser cutting machine is equipped with German Atlanta rack, Japanese Yaskawa motor and Taiwan Hiwin Rails. The positioning accuracy of the machine tool can be 0.02mm and the cutting acceleration is 1.5G. The working life is up to more than 15 years.

LXSHOW fiber laser cutting machine is equipped with German Atlanta rack, Japanese Yaskawa motor and Taiwan Hiwin Rails. The positioning accuracy of the machine tool can be 0.02mm and the cutting acceleration is 1.5G. The working life is up to more than 15 years.