Laser Welding Machine - The Future of Manufacturing

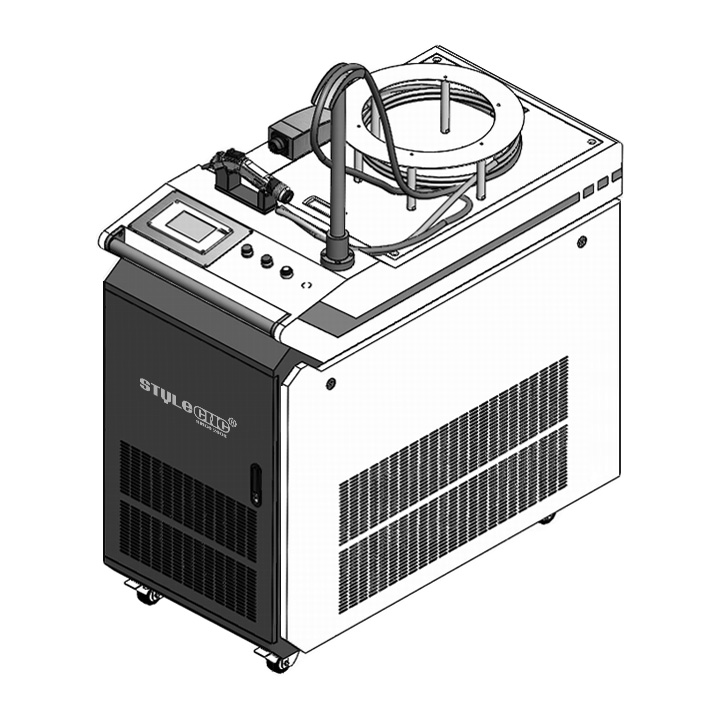

The use of laser welding machines has become increasingly popular in many manufacturing industries over the years. Non-contact laser welding is a highly precise and efficient method of welding metals and thermoplastics which provides many benefits for manufacturers. At BSA Machine Tools, we prioritize providing technical support and are dedicated to developing cutting-edge machinery for our clients. Our communication center houses professional laser cutting machines and laser welding and cleaning machines to assist in the manufacturing process.

With the emergence of Industry 4.0, smart manufacturing is becoming more popular than ever before. As a result, laser welding machines are becoming an essential component in manufacturing plants. By using laser welding technology, manufacturers can create highly accurate and intricate designs at a faster rate than traditional methods. Laser welding is perfect for industries that require high-speed welding and thin welding with low thermal malformation, such as the aerospace, automotive, and medical device industries.

A laser beam provides an excessive heat source that can penetrate deep into the material. This results in thin, deep welds that are not possible with other welding methods. The use of laser welding machines also reduces the occurrence of weld deformities, which is a common problem with traditional welding methods. Weld deformities include shrinkage, warpage, and distortion, which can result in structural damages, reduced durability, and increased production costs.

At BSA Machine Tools, we believe that the future of manufacturing lies in smart factories that are equipped with state-of-the-art machinery. Our team is dedicated to working with manufacturers to create smarter manufacturing processes. We are continually developing our technologies to ensure that our clients have what they need to succeed. Our focus on innovation and technical support will help manufacturers achieve their production goals with greater speed, efficiency, and precision.

In conclusion, laser welding machines are the future of manufacturing. Their precise and efficient capabilities provide manufacturers with many benefits, including high-speed welding and low thermal malformation. At BSA Machine Tools, our professional laser cutting machines and the laser welding and cleaning machines in our communication center help manufacturers create smarter manufacturing processes. By embracing Industry 4.0, we can build smarter plants and help companies create more efficient production processes.