•Great rigidity •High precision •No deformation during the life cycle •Welded aluminum chuck plate •High-precision process molding •Excellent dynamic performance

•Great rigidity •High precision •No deformation during the life cycle •Welded aluminum chuck plate •High-precision process molding •Excellent dynamic performance Pneumatic clamp design on both sides, can automatically adjust the center, adjustable diagonal range 20-220mm (320/350) optional

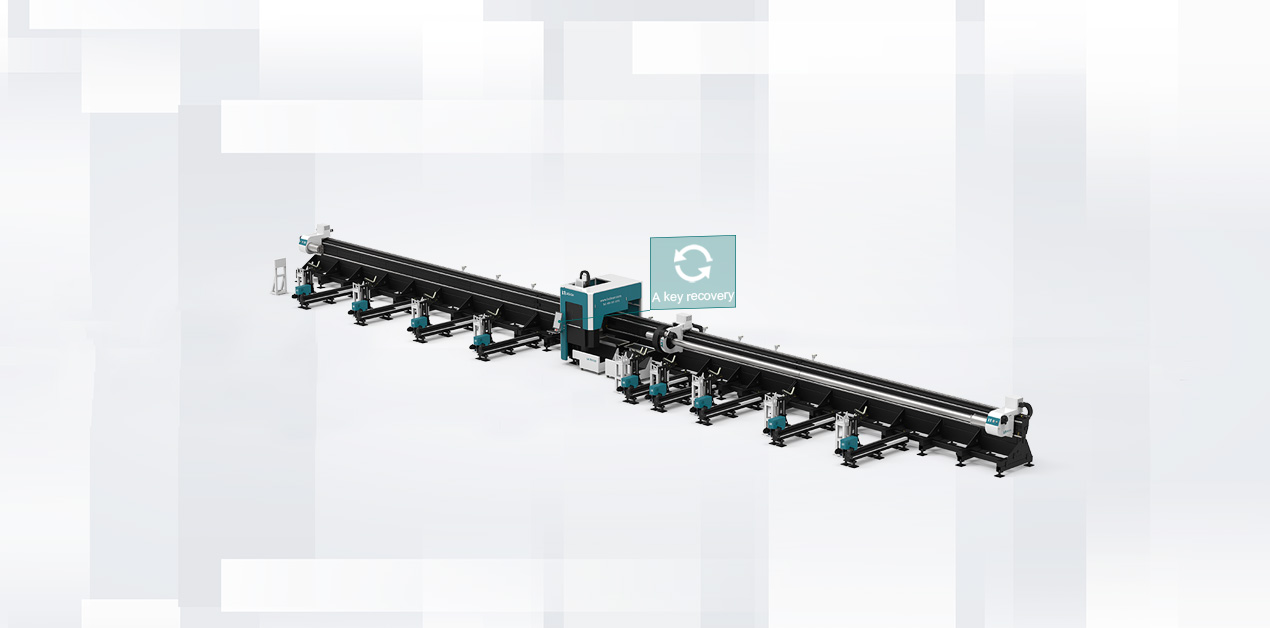

Pneumatic clamp design on both sides, can automatically adjust the center, adjustable diagonal range 20-220mm (320/350) optional  Adopt intelligent tube support design to solve the deformation problem in the process of cutting long tubes

Adopt intelligent tube support design to solve the deformation problem in the process of cutting long tubes ·Professional fixture design ·Automatic pneumatic chuck, adjustable and stable, with wider clamping range and greater clamping force. ·Non-destructive pipe clamping, fast and automatic centering clamping of pipes, more stable performance. ·The chuck size is smaller, the moment of inertia is low, and the dynamic performance is strong. ·Self-centering pneumatic chuck, gear transmission mode, higher transmission efficiency. ·Long working life and high working reliability. 1 Lead time: 15-25 working days 2 Payment Term: T/T;Alibaba trade assurance;West Union;Payple;L/C. 3 Laser Power: 3000-12000W 4 Brand: LXSHOW 5 Warranty: 3 years 6 Shipping: By sea/By air/By Railway

·Professional fixture design ·Automatic pneumatic chuck, adjustable and stable, with wider clamping range and greater clamping force. ·Non-destructive pipe clamping, fast and automatic centering clamping of pipes, more stable performance. ·The chuck size is smaller, the moment of inertia is low, and the dynamic performance is strong. ·Self-centering pneumatic chuck, gear transmission mode, higher transmission efficiency. ·Long working life and high working reliability. 1 Lead time: 15-25 working days 2 Payment Term: T/T;Alibaba trade assurance;West Union;Payple;L/C. 3 Laser Power: 3000-12000W 4 Brand: LXSHOW 5 Warranty: 3 years 6 Shipping: By sea/By air/By RailwayHydraulic system

Adopts advanced integrated hydraulic system reduces the installation of pipelines and ensures a high degree of reliability and safety in the operation of the machine. The speed of the slider movement can be realized. Rapid descent, slow bending, fast return back action, and fast down, slow down speed can be adjusted appropriately.

Electric control system

Eletrical component and material meet international standards,safe,reliable and long life. The machine adopts 50HZ, 380V three-phase four-wire power supply.The motor of machine adopts three-phase 380V and the line lamp adopts single phase-220V.The control transformer adopts two-phase 380V.The output of the control transformer is used by the control loop, among which 24V is used for back gauge control and for electromagnetic reversing valves. 6V supply indicator, 24V supply other control components. The electrical box of the machine is located on the right side of the machine and is equipped with a door opening and power-off device.The operate component of machine are all concentrated on the electrical box except the foot switch, and the function of each operating stacked element is marked by the image symbol above it.It can automatically cut off the power supply when opening the electric box door, and if it needs to be repaired live, it can be manually reset to pull out the micro switch lever.

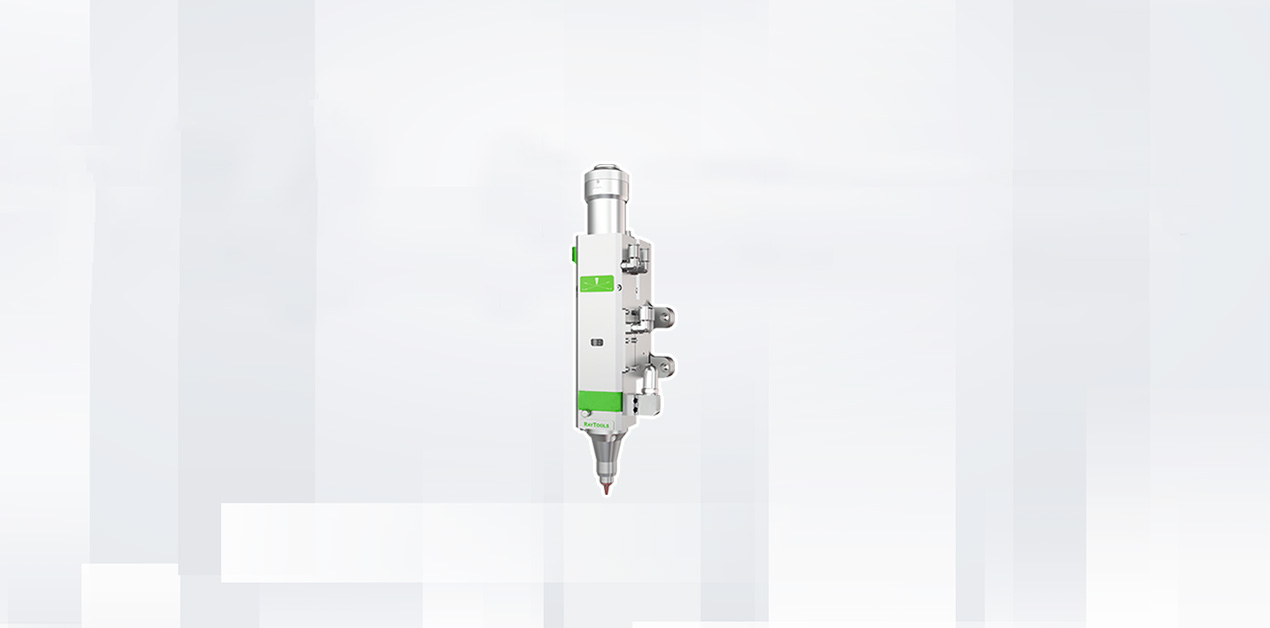

·Efficient Cooling Both the collimating lens and the focusing lens group are cooling structures, and the cooling air nozzle is added at the same time, which effectively protects the nozzle and ceramic body and prolongs the working time. ·Chasing Aperture Through the aperture of 35 mm, the interference of stray light is effectively reduced. ·Auto focus Auto focus, reduce human interference, focus speed 10m/min, repeatability 50 microns 25mm carbon steel plate pre-punching time <3s@3000w, greatly improving cutting efficiency.The system is equipped with a servo motor, and it does not need to be reset when it is turned on. If the power is cut off, the cutting operation can be resumed with one button.

·Efficient Cooling Both the collimating lens and the focusing lens group are cooling structures, and the cooling air nozzle is added at the same time, which effectively protects the nozzle and ceramic body and prolongs the working time. ·Chasing Aperture Through the aperture of 35 mm, the interference of stray light is effectively reduced. ·Auto focus Auto focus, reduce human interference, focus speed 10m/min, repeatability 50 microns 25mm carbon steel plate pre-punching time <3s@3000w, greatly improving cutting efficiency.The system is equipped with a servo motor, and it does not need to be reset when it is turned on. If the power is cut off, the cutting operation can be resumed with one button.

Front and back gauge

Front bracket: It is Placed on the side of the worktable and secured by screws. It can be used as a support when bending wide and long sheets. Back gauge: It adopts back gauge mechanism with ball screw and linear guide is driven by servo motor and a synchronous wheel timing belt. The high-precision positioning stop finger can be easily moved left and right on the double linear guide rail beam, and the workpiece is bent "as you like".