| Model | LX9TQA |

| Laser Power | 1000/1500/2000/3000W |

| Length of laser wave | 1070nm±5nm |

| Type of Laser | Single mode |

| 30% | |

| Work Mode | Continuous light |

| Power range | 5-95% |

| Power Unstabilit | 2% |

| Transmission fiber core | 25um-50um |

| Length of Fiber | 10m |

| Cooling way | Water cooling |

| Water chiller model | 1.OP/1.5P/2.0P |

| Cooling water temperature | 20-25℃ |

| Power | AC 220V±10% AC380±10%,50/60Hz |

| Temperature of work environment | 10~35℃ |

| Humidity of work environment | ≤95% |

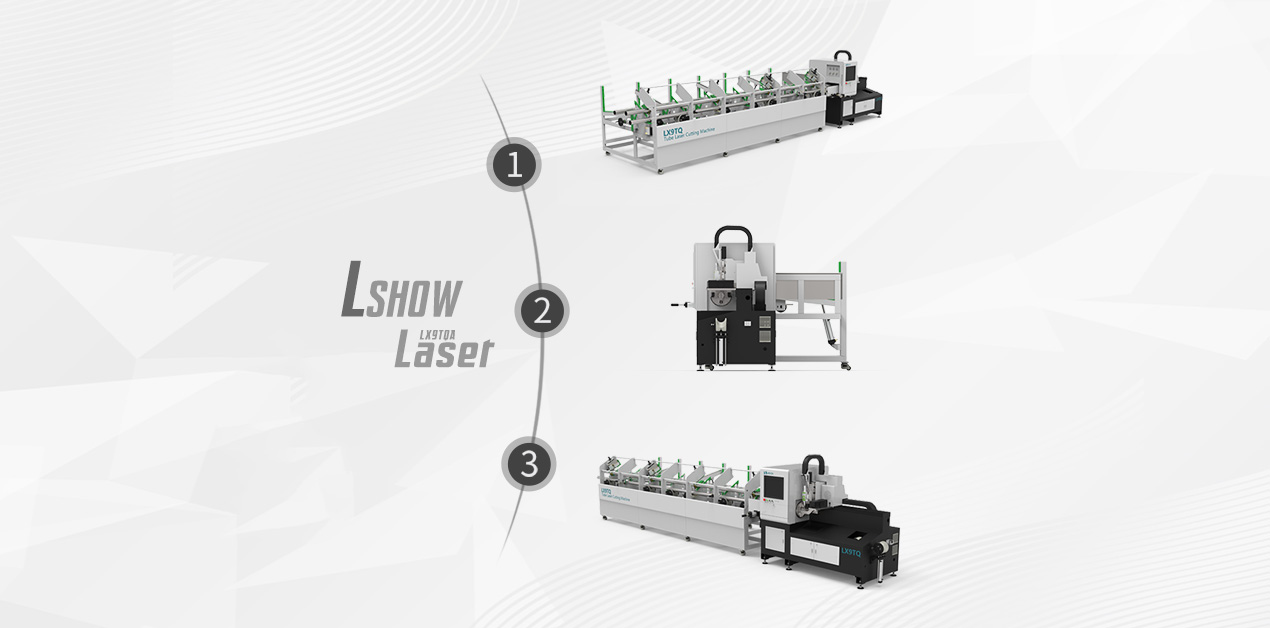

- Wide Cutting Range ,Easy Operation:

- Small blind area of tailings, saving materials and reducing post-process:

- Following-up cutting:

- Automatic identification of head and tail material:

Machine bed adopts strict welding and annealing process to ensure long-term stable operation and cutting accuracy of the equipment. After each welding seam of the bed is completed, an infrared flaw detector is used to detect whether there is a phenomenon of virtual welding or de-soldering, so as to ensure the welding quality. The unique constant temperature type bed stress relief annealing process is adopted. Each time the temperature rises by one degree, the temperature will be kept constant to ensure that the whole bed reaches the same temperature, and then the next stage of heating is carried out.After the multi-stage heating process, the machine bed will be cooled with the furnace, so as to ensure the elimination of residual stress in the weldings of the bed, stabilizing the bed size and shape, and ensure that the bed will not be deformed during the life cycle.

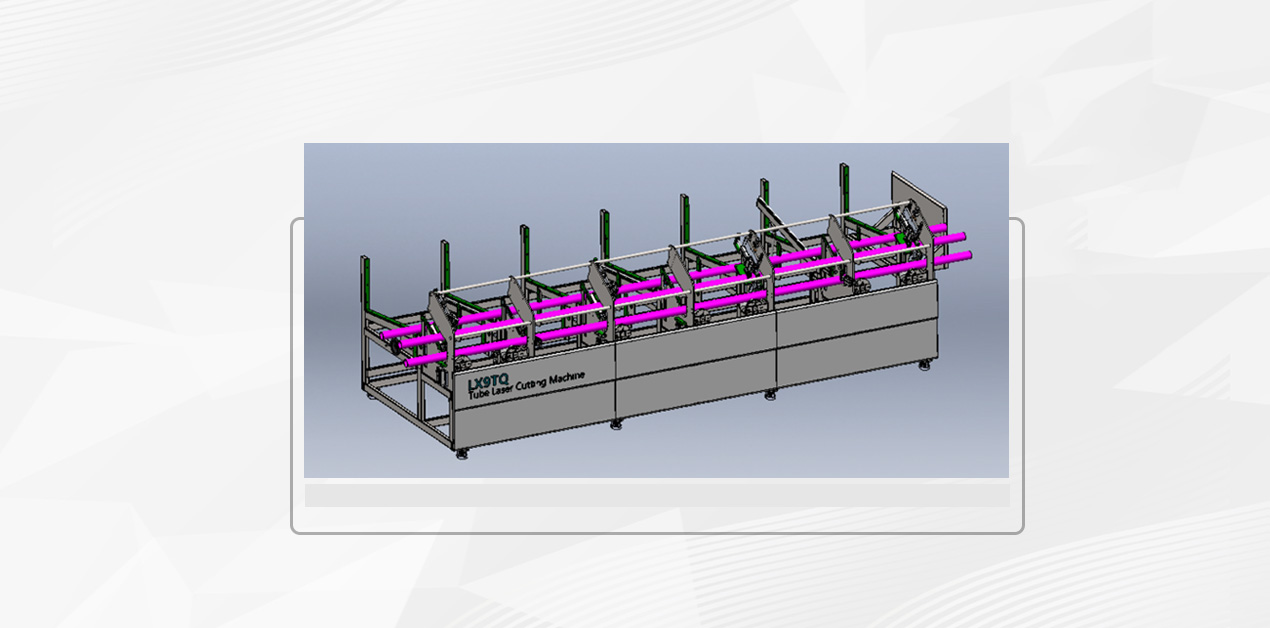

Machine bed adopts strict welding and annealing process to ensure long-term stable operation and cutting accuracy of the equipment. After each welding seam of the bed is completed, an infrared flaw detector is used to detect whether there is a phenomenon of virtual welding or de-soldering, so as to ensure the welding quality. The unique constant temperature type bed stress relief annealing process is adopted. Each time the temperature rises by one degree, the temperature will be kept constant to ensure that the whole bed reaches the same temperature, and then the next stage of heating is carried out.After the multi-stage heating process, the machine bed will be cooled with the furnace, so as to ensure the elimination of residual stress in the weldings of the bed, stabilizing the bed size and shape, and ensure that the bed will not be deformed during the life cycle. The machine can realize fully automatic feeding.It is only necessary to hoist the raw materials into the storage rack in batches: automatic loading → automatic feeding → automatic cutting → automatic blanking of the whole process. square pipes, round pipes and elliptical pipes all can be fully automatic loading。 Fast loading speed and high loading accuracy.

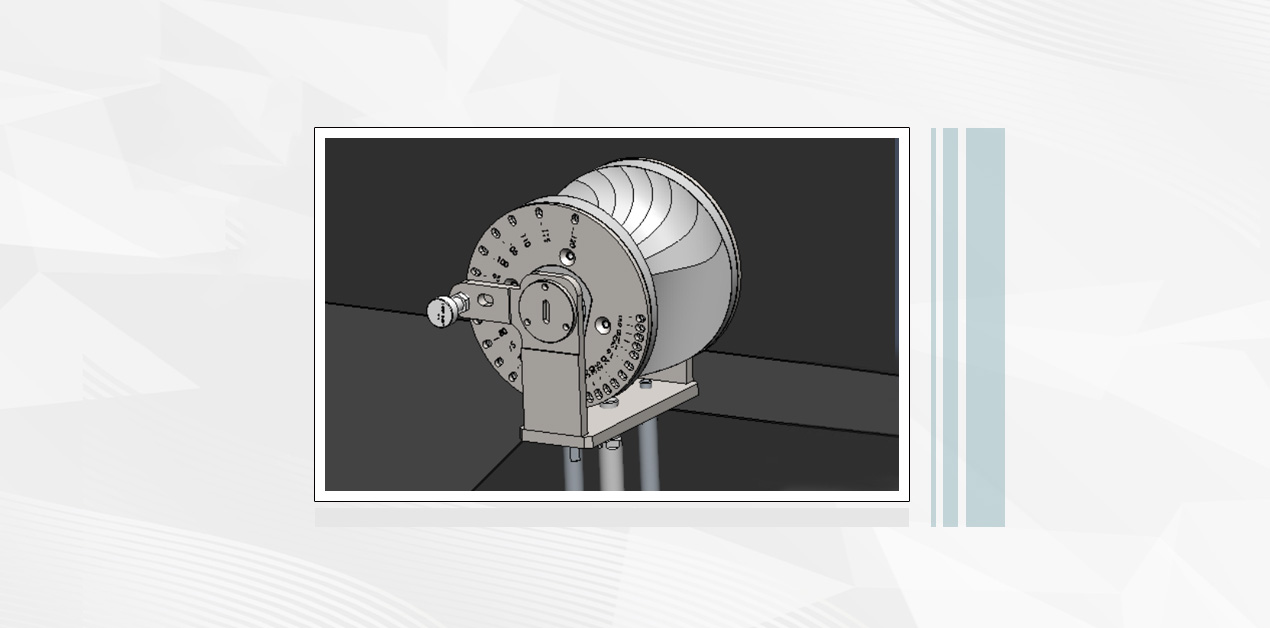

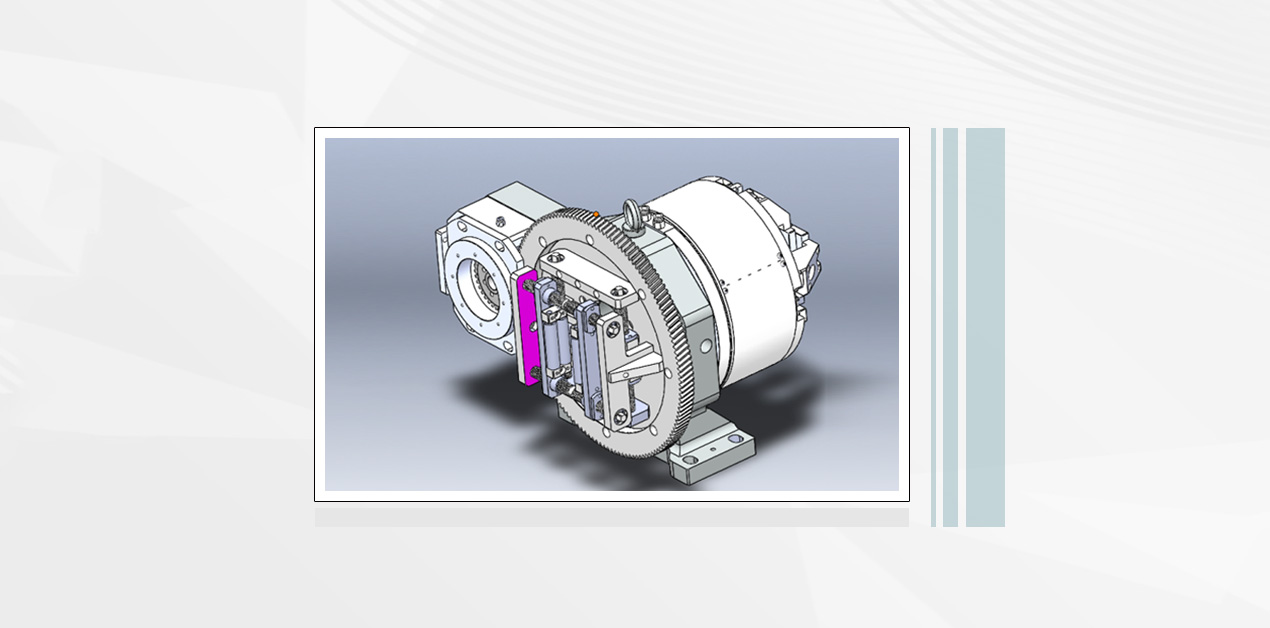

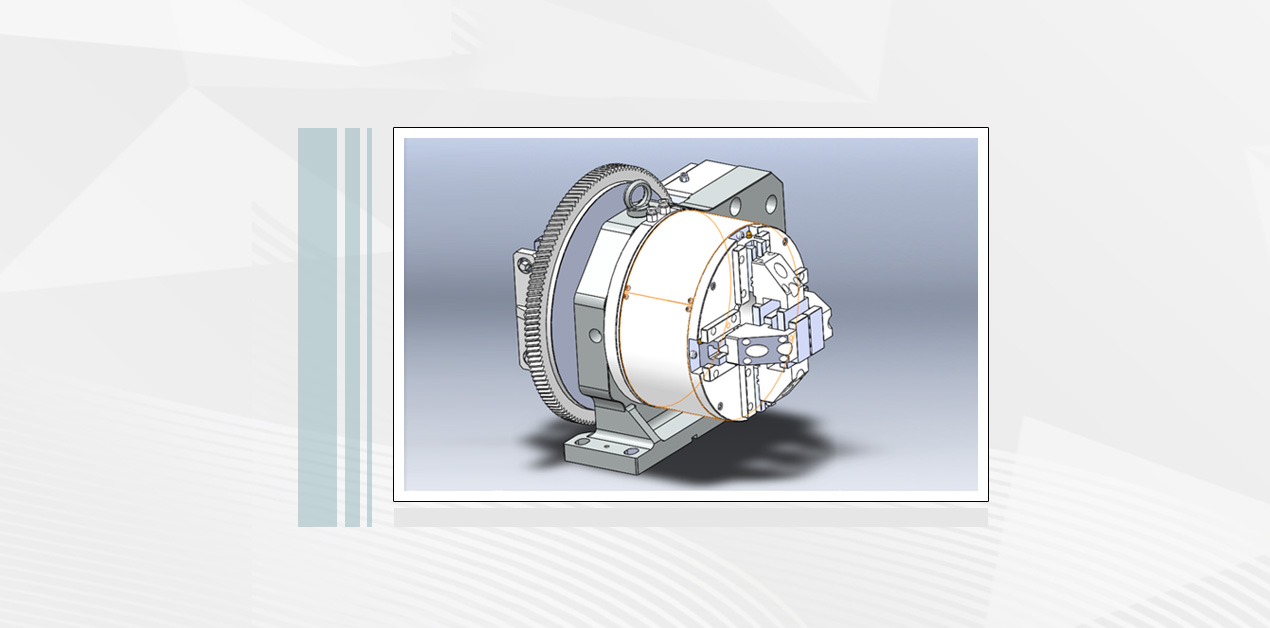

The machine can realize fully automatic feeding.It is only necessary to hoist the raw materials into the storage rack in batches: automatic loading → automatic feeding → automatic cutting → automatic blanking of the whole process. square pipes, round pipes and elliptical pipes all can be fully automatic loading。 Fast loading speed and high loading accuracy. The pneumatic chuck adopts a double-sided clamping mechanism, which increases the support points of the pipe during cutting process and improves the cutting accuracy.

The pneumatic chuck adopts a double-sided clamping mechanism, which increases the support points of the pipe during cutting process and improves the cutting accuracy.Application Materials:

Fiber Laser Metal Cutting Machine is suitable for metal cutting like Stainless Steel Tube, Mild Steel Tube, Carbon Steel Tube, Alloy Steel Tube, Spring steel Tube, Iron Pipe, Galvanized Steel Tube, Aluminum Pipe, Copper Tube, Brass Tube, Bronze Pipe, Titanium Pipe, Metal Tube, Metal Pipe, etc.

Application Industries:

Fiber Laser Cutting Machines are widely used in manufacture Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Tube Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

FOB Reference Price Range USD: 10000-50000 Model Number:LX9TQA Lead time:10-25 working days Payment Term:T/T;Alibaba trade assurance;West Union;Payple;L/C.Machine Size:(About)1000*2600*1500mm (Only machine main parts) Machine weight:1000KG(Only machine main parts) Brand:LXSHOW Warranty:3 years Shipping:By sea/By land

FOB Reference Price Range USD: 10000-50000 Model Number:LX9TQA Lead time:10-25 working days Payment Term:T/T;Alibaba trade assurance;West Union;Payple;L/C.Machine Size:(About)1000*2600*1500mm (Only machine main parts) Machine weight:1000KG(Only machine main parts) Brand:LXSHOW Warranty:3 years Shipping:By sea/By land Equipped with a universal high-precision pneumatic chuck, it solves the shortcoming that this type of pipe cutting machine needs to replace the fixture frequently, and can realize the cutting and processing of pipes of different specifications without changing the fixture.Equipped with profiling drag rollers to prevent pipe deformation and sagging.

Equipped with a universal high-precision pneumatic chuck, it solves the shortcoming that this type of pipe cutting machine needs to replace the fixture frequently, and can realize the cutting and processing of pipes of different specifications without changing the fixture.Equipped with profiling drag rollers to prevent pipe deformation and sagging.